Pressure Vessel & Tank Manufacturing

Userful Links

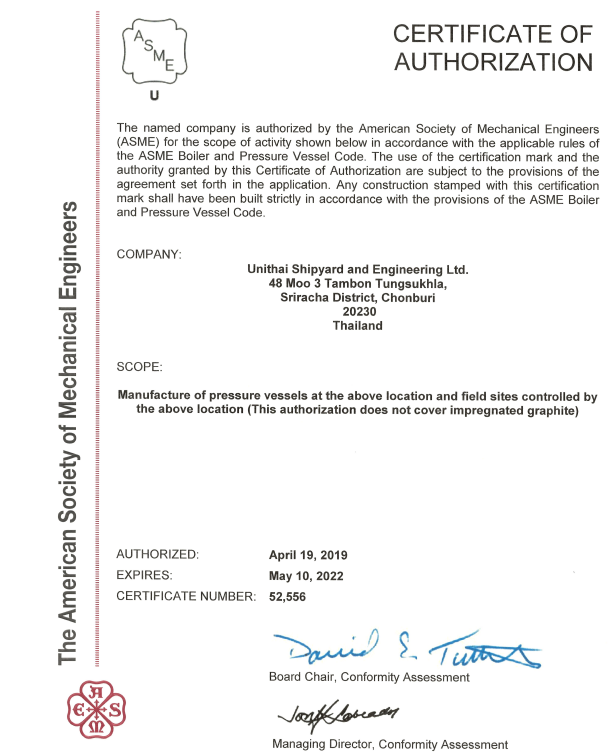

ASME U & U2, and R Stamp Certification

At Unithai we design and manufacture Pressure Vessels for our customers in compliance with the ASME Section VIII Div. 1 and Div. 2.

Our capability is to manufacture large diameter, heavy weight pressure vessels for a range of industrial sectors including Petrochemical, Wastewater, Pharmaceutical, Oil & Gas and Renewable Energies.

Our onshore services repair include:

- Plant maintenance & repairs

- Shutdowns / turnarounds

- Emergency repairs (immediate response)

- Field erected equipment

- Construction

- Piping installation

- HRSG (Cogen) erection

- Heat Exchanger bundle pulling and rebuild

- In-situ overlay and specialty welding

- Boiler maintenance and rebuild

- Vessel tray installation

Additional service are:

- Design (PV Elite, PV Fabricator and NozzlePro software).

- Fabrication

- Plate roll up to 130 mm

- Insulation

- Testing

- Installation

- Coating

- Hydrostatic Test

- Post Weld Heat Treatment

- Other low temperature applications

Products:

- Pressure Vessel manufacture Size 2- 6 Diameter

- Storage Tanks Size 6 -50 Diameter

- LNG Tanks

- LPG Bullets

- Process Pressure Vessels

Material:

- Carbon

- P265 GH Carbon Steel

- SA516 Gr60 & SA516 Gr70 Carbon Steels

- 304/304L & 316/316L Stainless Steels Stainless

- 9%Ni

Facilities:

- 3,240 m2 Workshop equipped with 2x 50 ton overhead cranes

- Four Roll Plate Rolls x 4 meters wide

- Roll Carbon Steel plate 25mm – 130 mm thickness

- CNC Plate cut & bevelling machine

- CNC Pipe nozzle cut and bevel machine

- Submerged Arc Welding (SAW) 1200amp

- Tandem Arc weld process

- SAW Column & Boom with 7 meter reach

- 20 ton, 40 ton & 120 ton Weld Rotators

- In-house Jetty for direct load out to Sea Transportation